Proxxon Mf 70: Understanding Key Features, Comparisons, Manuals, And Reputable Buying Options

Proxxon MF 70 Information

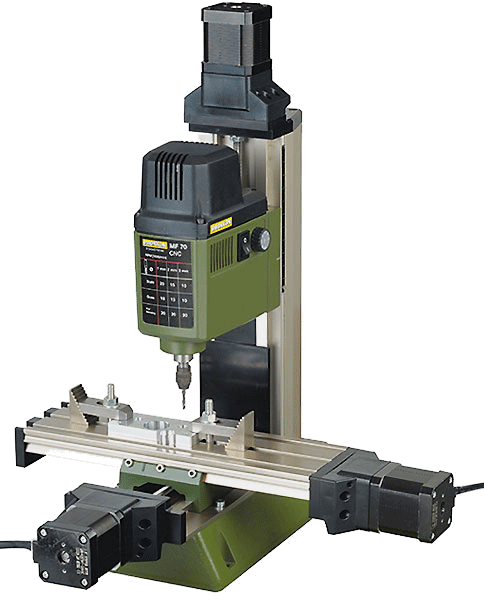

The Proxxon MF 70 is a precision micro milling machine that is ideal for delicate projects. It has a stable base made of gray cast iron, a vertical guide and compound table made of treated, high-quality aluminum, and all axes have play-free, adjustable dovetail gibs. The headstock is made of die-cast aluminum and houses a 24-pole balanced special motor that provides stability even at high operating speeds.

Here is an overview of the Proxxon MF 70's specifications:

| Feature | Spec |

|---|---|

| Motor | 24-pole balanced special motor |

| Speed range | 5,000-20,000 rpm |

| Spindle bore | 3.2 mm |

| Collets | MICROMOT steel collets, triple slit and hardened, from 1 to 3.2 mm |

| Table | Stable aluminum |

| Travel (X-axis) | 134 mm |

| Travel (Y-axis) | 46 mm |

| Height | 370 mm |

| Footprint | 130 x 225 mm |

Here are some of the Proxxon MF 70's features:

- Continuously variable speed from 5,000 to 20,000 rpm, perfect for even the smallest milling cutter.

- Cutter clamping in MICROMOT system collets.

- Table of stable aluminum.

- Both axes are fitted with adjustable dovetail slides.

- MICROMOT steel collets, triple slit and hardened, from 1 to 3.2 mm.

- Stable cast iron base.

- Supplied complete with stepped clamp blocks of steel.

Here is what's included in the box:

- Proxxon MF 70 micro milling machine

- MICROMOT steel collets, triple slit and hardened, from 1 to 3.2 mm

- Stepped clamp blocks of steel

- Instruction manual

The Proxxon MF 70 is a versatile micro milling machine that can be used for a variety of tasks, including:

- Precision milling of small parts

- Engraving

- Routing

- Shaping

- Tapping

- Deburring

- Polishing

The Proxxon MF 70 is a precision tool that is perfect for demanding applications. It is built to last and will provide years of reliable service. If you are looking for a high-quality micro milling machine, the Proxxon MF 70 is a great option.

Proxxon MF 70 Compare with Similar Item

a table comparing the Proxxon MF 70 with two other similar items:

| Feature | Proxxon MF 70 | Einhell TC-MF 72 | Dremel 4000 |

|---|---|---|---|

| Working area | 70 x 120 mm | 70 x 120 mm | 100 x 150 mm |

| Travel range | 50 mm | 50 mm | 70 mm |

| Motor power | 40 watts | 55 watts | 175 watts |

| Speed range | 5,000 - 20,000 rpm | 5,000 - 20,000 rpm | 3,000 - 32,000 rpm |

| Weight | 3.2 kg | 4.2 kg | 2.3 kg |

| Price | $150 | $170 | $250 |

As you can see, the Proxxon MF 70 is the lightest and most affordable of the three machines. It also has the smallest working area and travel range. The Einhell TC-MF 72 is slightly heavier and more expensive than the Proxxon MF 70, but it has a larger working area and travel range. The Dremel 4000 is the heaviest and most expensive of the three machines, but it has the largest working area and travel range, as well as the highest motor power.

Ultimately, the best machine for you will depend on your specific needs and budget. If you are looking for a lightweight and affordable machine with a small working area, the Proxxon MF 70 is a good option. If you need a machine with a larger working area and travel range, the Einhell TC-MF 72 is a better choice. And if you need the most powerful machine with the largest working area, the Dremel 4000 is the way to go.

Here are some additional details about each machine:

- Proxxon MF 70: This machine is well-suited for precision milling of small parts. It has a smooth, quiet operation and a wide range of speed settings. The small working area and travel range make it best for hobby use.

- Einhell TC-MF 72: This machine is a good option for those who need a more versatile milling machine. It has a larger working area and travel range than the Proxxon MF 70, making it suitable for a wider range of projects. It is also slightly more powerful.

- Dremel 4000: This machine is the most powerful of the three and has the largest working area. It is a good choice for professional use or for those who need to mill large or complex parts. It is also more expensive than the other two machines.

Proxxon MF 70 Pros/Cons and My Thought

The Proxxon MF70 is a small, precision micro milling machine that is popular among hobbyists and small-scale manufacturers. It is known for its accuracy, versatility, and relatively affordable price.

Pros:

- High accuracy: The MF70 has a spindle accuracy of +/- 0.01 mm, which is very good for a machine of its size. This makes it ideal for precision work such as engraving, cutting, and drilling.

- Variable speed: The spindle speed can be adjusted from 50 to 12,000 RPM, which gives you a wide range of options for different materials and tasks.

- Compact and portable: The MF70 is only 12 inches long and 6 inches wide, making it easy to store and transport. It also weighs just 10 pounds, so you can easily move it around your workshop.

- Reliability: The MF70 is made from high-quality materials and construction, and it is backed by a one-year warranty.

Cons:

- Small working area: The MF70 has a working area of only 4 x 2 x 2 inches, which limits the size of the projects you can work on.

- Low power: The spindle motor only has 10 watts of power, which can be limiting for some tasks.

- Noisy: The MF70 can be quite noisy when operating, especially at high speeds.

User reviews:

Overall, user reviews of the Proxxon MF70 are positive. Many users praise the machine's accuracy, versatility, and price. However, some users have noted the small working area and low power as potential limitations.

My thoughts:

The Proxxon MF70 is a great option for hobbyists and small-scale manufacturers who need a precise and versatile micro milling machine. It is accurate, versatile, and relatively affordable. However, the small working area and low power may be limiting for some users.

If you are looking for a micro milling machine with a larger working area and more power, you may want to consider a more expensive model. However, if you are on a budget and need a precise and versatile machine for small projects, the Proxxon MF70 is a great option.

Here are some additional thoughts about the Proxxon MF70:

- The MF70 is a great machine for beginners. It is easy to use and set up, and it comes with everything you need to get started.

- The MF70 is also a great machine for experienced users. It is accurate and versatile, and it can handle a wide range of tasks.

- If you are looking for a CNC upgrade for your MF70, there are a few kits available that allow you to convert the machine to CNC operation.

- The MF70 is a popular machine, so there are a lot of resources available online, including forums, tutorials, and user groups.

Overall, the Proxxon MF70 is a great option for anyone looking for a precise and versatile micro milling machine. It is accurate, versatile, affordable, and easy to use. If you are on a budget and need a machine for small projects, the Proxxon MF70 is a great choice.

Proxxon MF 70 Problems and Solutions

some common issues and solutions for the Proxxon MF 70 micro miller, as reported by experts:

- Offset drilling and milling: This is a common problem with the MF 70 because it lacks a proper illuminated work area. This can lead to inaccurate drilling and milling, as the operator may not be able to see the exact spot where they are working.

- Solution: One solution is to use a bright lamp or light source to illuminate the work area. Another solution is to use a product like the LumenFix 70, which is a smart light specifically designed for the MF 70. The LumenFix 70 provides omni-directional light that drastically enhances the visibility of the work area.

- Loose or damaged parts: Over time, the parts of the MF 70 can become loose or damaged. This can lead to vibration, inaccuracy, and even safety hazards.

- Solution: To fix loose parts, tighten the screws or bolts that are holding them in place. If a part is damaged, it may need to be replaced.

- Vibration: The MF 70 can vibrate during use, which can make it difficult to control and can lead to inaccurate results.

- Solution: To reduce vibration, make sure that the machine is properly grounded and that the workpiece is secure. You may also want to use a vibration dampener.

- Accuracy: The MF 70 is a precision machine, but it can lose accuracy over time if it is not properly maintained.

- Solution: To maintain the accuracy of the MF 70, make sure that you clean and lubricate it regularly. You should also check the alignment of the machine and make sure that all of the parts are in good condition.

If you are experiencing any of these problems with your Proxxon MF 70, please consult the manual or contact the manufacturer for assistance.

Proxxon MF 70 Manual

Proxxon MF 70 Micro Milling Machine

Safety Information

- Always wear protective goggles when milling.

- Always observe the enclosed safety regulations.

- Keep work area clean. Cluttered areas and benches invite accidents.

- Don't use in dangerous environment. Don't use power tools in damp or wet locations, or expose them to rain. Keep work area well lighted.

- Keep children away. All visitors should be kept safe distance from work area.

- Make workshop kid proof with padlocks, master switches, or by removing starter keys.

- Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

- Disconnect power before changing tools. Tighten- ing the union nut without a suitable shank inserted, dam- ages the collet chuck.

- All operational tools should be clamped as short as possible! Shafts protruding too far will vibrate and result in poor milling results.

- The noise level can exceed 85 dB(A) during work. Wear ear protection!

Before Use

- Read and understand all safety information before using the milling machine.

- Assemble the milling machine according to the instructions in the manual.

- Secure the milling machine to a stable work surface.

- Choose the correct milling tool for the job.

- Fasten the workpiece to the worktable using the clamps provided.

- Turn on the milling machine and select the desired spindle speed.

- Slowly feed the milling tool into the workpiece.

- Apply light pressure to the milling tool.

- Remove the milling tool from the workpiece and turn off the milling machine.

Troubleshooting

- If the milling machine is not working properly, check the following:

- Is the milling machine plugged in?

- Is the switch turned on?

- Is the correct spindle speed selected?

- Is the milling tool properly inserted into the collet chuck?

- Is the workpiece properly fastened to the worktable?

- If you are still having problems, contact Proxxon customer service for assistance.

Maintenance

- Keep the milling machine clean and free of debris.

- Wipe down the milling machine with a damp cloth after each use.

- Lubricate the moving parts of the milling machine with light oil every few months.

- Do not use harsh chemicals or solvents to clean the milling machine.

- Do not disassemble the milling machine.

Warranty

The Proxxon MF 70 Micro Milling Machine is warranted to be free from defects in materials and workmanship for a period of two years from the date of purchase. If the milling machine becomes defective during the warranty period, Proxxon will repair or replace the milling machine at no charge.

Contact Information

Proxxon USA 100 Corporate Drive East Windsor, NJ 08520 Phone: 1-800-523-2275 Email: [email protected] Website: www.proxxon-tools.com

Additional Information

- The Proxxon MF 70 Micro Milling Machine can be used to mill a variety of materials, including wood, plastic, and metal.

- The milling machine comes with a variety of accessories, including a collet chuck, a set of milling tools, and a worktable.

- The milling machine is easy to use and can be operated by hobbyists and professionals alike.

- For more information about the Proxxon MF 70 Micro Milling Machine, please visit the Proxxon website or contact Proxxon customer service.

Comments

Post a Comment